|

Faceted

Glass Beads - Fire Polish

Posted 7/6/05

Faceting of stone beads has been going on for a long time,

and in Germany faceted beads out of Idar Oberstein are world

known as the best in existence. Glass beads are a more recent

occurrence, relatively speaking, as pressed beads only came into

existence in Gablonz, Austria in 1829, when the first molded

beads were shown at a trade fair in Prague. After that, round

glass beads would have been faceted using the same techniques

as stone faceting in Idar Oberstein. The technicians lay face

down on a bench and pressed the beads onto a stone grinding wheel,

with water running over the stone to keep the dust down. These

early glass faceted beads would have been used in the African

trade market, and can still be found today for sale by African

Traders at the various shows around the country.

These early attempts at faceting were rather primitive, as

glass was not considered very valuable or worthy of much effort

in polishing, as the stone beads were. So, being innovative,

the German bead makers invented firepolishing.

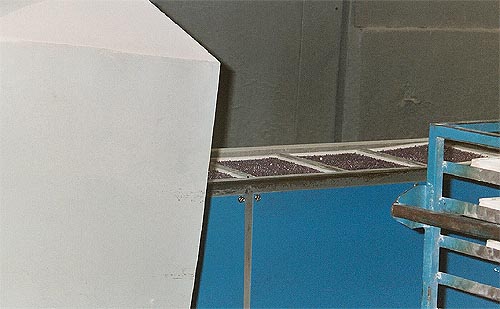

After

the glass bead has been pressed in a mold, and faceted into the

desired amount of cuts, it is run through a heating furnace that

is actually not a flame at all, just an extremely high temperature,

that puts a gloss on the faceted surface of the beads, in effect

polishing it. The machine itself looks like a 20 foot long metal

box, with a conveyor belt running through it. The beads are placed

on metal pie trays, one layer of beads deep, and run through

the heating box. The name firepolish is actually a misnomer,

it should be called heatpolished. After

the glass bead has been pressed in a mold, and faceted into the

desired amount of cuts, it is run through a heating furnace that

is actually not a flame at all, just an extremely high temperature,

that puts a gloss on the faceted surface of the beads, in effect

polishing it. The machine itself looks like a 20 foot long metal

box, with a conveyor belt running through it. The beads are placed

on metal pie trays, one layer of beads deep, and run through

the heating box. The name firepolish is actually a misnomer,

it should be called heatpolished.

Then after they are cooled down, any extra coatings are attached

to them, if required. Examples of different coatings would be

AB, vetrails, pearlized, or bronzing. These coatings would either

be dipped, or sprayed, and then either heated or baked on, or

laquered over, if it is a pearlized coating.

The first firepolish was just your basic transparent and opague

glass, in 3mm, 4mm, 6mm and 8mm round shapes. Currently, round

facetted firepolish comes in those sizes as well as 10mm, 12mm,

14mm, 18mm, 20mm and 22mm. There are also teardrop shapes offered

in 7x5mm, and 9x7mm.

The

technique used today in Czech Republic is basically the same

as in Germany, but now the technician stands up straight in front

of the grinding wheel, which is approximately 8 feet in diameter.

There is a ratchet attached to the wheel, which has an attachable

piece of equipment with multiple holes in a line on it. The technician

scoops this piece of equipment into the bucket of glass beads

at his/her side, and the beads fall part way into the holes.

The technician secures the beads so they wont fall out, attaches

the equipment to the ratchet, and presses it against the revolving

grinding wheel. Water is run over the wheel, and the bead is

ground against the wheel for a few seconds, then released, the

ratchet is applied, the beads turn a little, pressure is again

applied to the wheel on a new section of the bead, and this is

done until the bead is totally faceted all the way around. The

equipment is then unattached from the rachet, the beads dumped

into another bucket, and the procedure is repeated. The room

in which this is done might have up to 20 or more wheels, and

the noise is deafening. The air is hot and moist from the water

and all the machinery running, and is most uncomfortable to be

in for any length of time. The

technique used today in Czech Republic is basically the same

as in Germany, but now the technician stands up straight in front

of the grinding wheel, which is approximately 8 feet in diameter.

There is a ratchet attached to the wheel, which has an attachable

piece of equipment with multiple holes in a line on it. The technician

scoops this piece of equipment into the bucket of glass beads

at his/her side, and the beads fall part way into the holes.

The technician secures the beads so they wont fall out, attaches

the equipment to the ratchet, and presses it against the revolving

grinding wheel. Water is run over the wheel, and the bead is

ground against the wheel for a few seconds, then released, the

ratchet is applied, the beads turn a little, pressure is again

applied to the wheel on a new section of the bead, and this is

done until the bead is totally faceted all the way around. The

equipment is then unattached from the rachet, the beads dumped

into another bucket, and the procedure is repeated. The room

in which this is done might have up to 20 or more wheels, and

the noise is deafening. The air is hot and moist from the water

and all the machinery running, and is most uncomfortable to be

in for any length of time.

Talking to the managers or owners of the different faceting

departments of the firepolish factories, it was brought to my

attention that Czech workers refuse to perform these duties,

and foreign workers from Poland, Slovakia and the Ukraine are

the people who do most of the faceting.

Once the beads are finished being coated, firepolished, inspected,

etc… they are then strung on cotton thread. This can be

done either by machine or by hand. The factories we deal with

farm out the work to people in the local villages who supplement

their income by stringing the beads on a part time basis. The

factory drops off sacks of beads with instructions on how they

are to be strung; ie: 25 beads to a strand, 12 strands to a bundle,

4 bundles to a mass, x number of masses to the sack they are

given. When the job is done, the factory comes back and picks

up the beads, and pays off the workers. Usually it is the women

and children who do this work. If the beads are round, they can

use a machine that looks like a treadle sewing machine, but with

a large bowl on top. The beads are poured into the bowl, and

12 needles are laid into the bowl, which is spun around and beads

get threaded onto the needles and run along miles of thread.

When a large amount of beads are on the thread, the strands are

measured off in the quantity required and tied off.

Some of the factories we use are so small that all the work

is done cottage industry style. The beads are pressed at one

place, by an experienced presser, then it is shipped off to a

faceter, then taken to a larger factory where it is firepolished,

then distributed to the stringers. If a coating needs to be applied,

the beads might then first be sent to a coating facility, then

baked, then strung. If the bead maker is too small to handle

his own exporting, he will then take the beads to a packer, who

will pack the beads, then to an export agent who will prepare

the documents and handle the financing.

When you consider all the steps taken above to produce these

beads, it is amazing really how inexpensive they are to purchase.

They should be much higher.

|